What is Amorphous Silica?

- Amorphous means shapeless - not having any definite shape. Amorphous Silica are very light powders of silicon dioxide (SiO2) which can exhibit different properties.

- Most naturally found silica is crystalline in nature (sand, quartz). Even the amorphous silica found naturally (volcano eruptions etc.) has over 8% crystalline silica.

- Most amorphous silica is manufactured and are also called synthetic amorphous silica, although it is not a true depiction as Silica is finally sourced from nature.

- Properties of Amorphous Silica is controlled through the manufacturing process and can lead to variety of products with different properties but referred to as Amorphous Silica.

- Synthetic Amorphous Silica manufactured through wet process is referred to as precipitated Silica and the source of Silica being mined quartz.

- Fumes Silica is manufactured in dry process – flame pyrolysis of silicon tetrachloride or quartz sand vaporised in a 3000 °C electric arc. While Fumed Silica offers high purity it is very expensive.

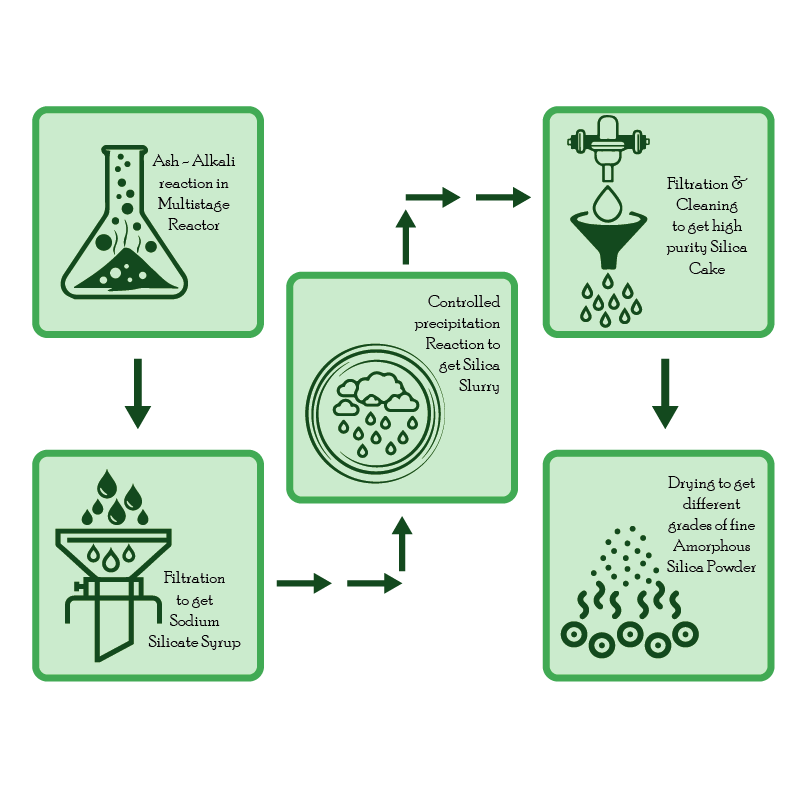

- Bio Silica is Amorphous Silica manufactured through wet process with the source of Silica being Rice Husk Ash – natural biogenic source and offers high purity economically.

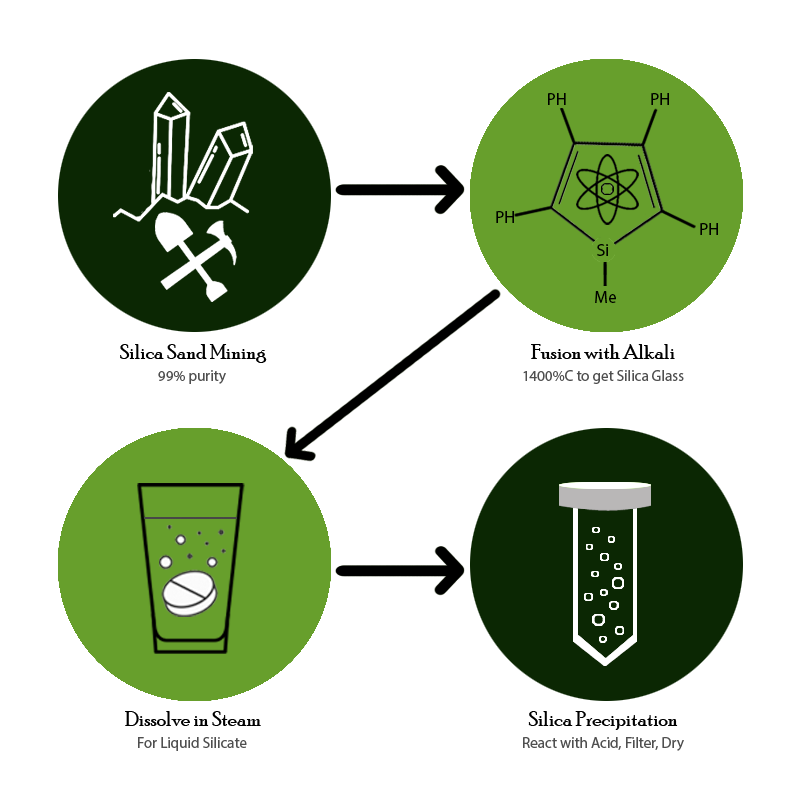

SILICA - Conventional Process

High Energy process. Silica Sand comes from mining.

Traces of heavy metals, impurities & unreacted silicate.

Bio Silica – Efficient Process

High Purity free from Heavy Metal & other toxic chemicals.

Eco-Friendly Low Energy, Uses Waste – Rice Husk Ash.

BALANCE THE MAGIC TRIANGLE

- High Purity with Zero Heavy Metal and very low impurities.

- Nature Friendly – Mined Raw Material replaced with waste. Reduce Energy requirement.

- Budget Friendly – Make high purity silica at economically.

Major Functions

01

Free Flowing Anti Caking Agent

Bio Silica has high moisture capturing capacity. When mixed with a powder substances it absorbs moisture ahead of the host powder and keep it free flowing.

Bio-Silica is broadly inert and hence is widely used for food (seasoning, spices, powdered mixes, namkeens etc), animal feed, medicines, insecticides, pesticides, fertilizers, industrial chemicals etc.

Carrying Agent

Bio Silica is extensively used to carry flavors, nutrients and active product ingredients. It converts difficult-to-handle liquids into powdered liquids or dry liquid concentrates to improve process efficiency and/or product performance.

It’s high absorption capacity & inert nature makes Bio Silica the most preferred carrier by food, pharma, agriculture input and home care industry.

02

03

Thickening Agent

Bio Silica is an excellent rheology modifier acting as a thickening agent. It is widely used with adhesives, sealants, engineered materials with complex formulation.

It helps achieve desired suspension performance, anti sag property without disturbing other system properties. It is effective in non-polar and medium-polar solvent systems.

Flatting & Matting Agent

Bio Silica acts as flatting and matting agents to reduce the gloss in coatings, paints, lacquers, varnishes and inks, while providing lower viscosity and better stir-in capability.

It also introduces surface hardness and abrasion resistance. Bio Silica with varied properties are used to improve dispersion stability and anti-settling behavior in solvent-borne and water-borne products.

04

05

Reinforcing Filler for Rubber, Tires and Paper.

Enhances rubber processing characteristics– faster cure rates, easier mixing, better flow etc.

In paper imparts strength and improves inert and hence is widely used for food (seasoning, spices, powdered mixes, namkeens etc), animal feed, medicines, insecticides, pesticides, fertilizers, industrial chemicals etc.k capture & retention.

Battery Separators

Bio Silica is widely used on lead-acid battery as microporous battery separator.

It is used to lower electrical resistance, increase puncture resistance, improve separator manufacturability and achieve other performance benchmarks.

Many more industries are looking at using Bio-Silica as an effective separator.

06

Impact of Silica Impurities

SULPHATE

May react with oil & other components. May change the colour and appearance of the product.

HEAVY METALS [Lead, Mercury, Arsenic]

Can breach the threshold level of acceptable limits in product.

CRYSTALLINE SILICA

Not recommended in most products.

FERROUS

May react with oil & other components. May change the colour and appearance of the product.

SALT

Imparts salty taste to the product. Disturbs product outcome and experience.

DOWNLOADS

FoodFlowSil

Food Grade Amorphous Silica for use as Anti Caking, Free Flowing & Active Carrier

Multi-Sil

Amorphous Silica for use as Anti Caking & Free Flowing Agent in various applications..

SiLatex

Silica for use in Rubber & Tire as a functional additive to enhancing various properties.

SDS - Silica

Safety Data Sheet for all grades of Amorphous Silica Products.